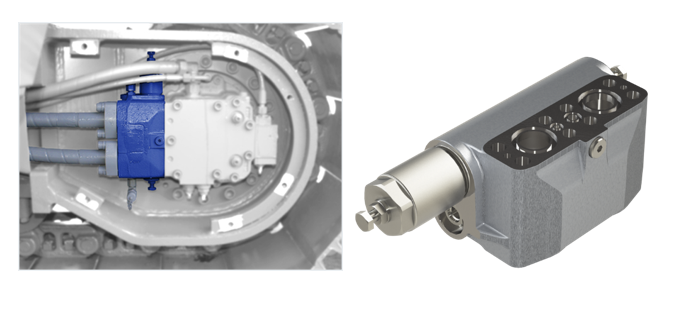

Brake valves are used as safety valves in hydraulically driven construction machinery. They prevent excessive speeds when traveling downhill. At the same time, they protect the travel motor from excessive speeds. The brake valve is flanged either on the travel motor of a wheeled excavator or on the drive motors of a crawler excavator. It can also be used for rotary motors of other applications.

More Informationen