WESSEL PILOT-OPERATED CHECK VALVE HYDRAULIC

Description

Load-holding valves or pilot-operated check valves are used to hold a hydraulic consumer leakage free in a certain position even if the spool of the main control valve leaks in the neutral position causing the load to drop. The locking is absolutely leak-free. The valves are seat-valves with hardened components. An integrated pressure relief valve protects the consumer in the locked state against excessive pressures. The unlocking of the check valve is done hydraulically via pilot pressure. The valve can be flanged directly onto the main control block of the construction machine

Characteristics

- Can be flanged onto the main control valve section

- Leakage free

- Pressure limiting function adjustable

- Low pressure losses

- Operate with pilot pressure

Technical specifications

| Design | Port sizes | Maximum pressure | Maximum flow |

|---|---|---|---|

| LHV-3N | SAE 3/4" | 420 bar | 300 l/min |

| LHV-3N | SAE 1 " | 420 bar | 400 l/min |

| LHV-3N | SAE 1-1/4" | 420 bar | 600 l/min |

Exampl of Applications

Lock a consumer leakage free at the main control valve

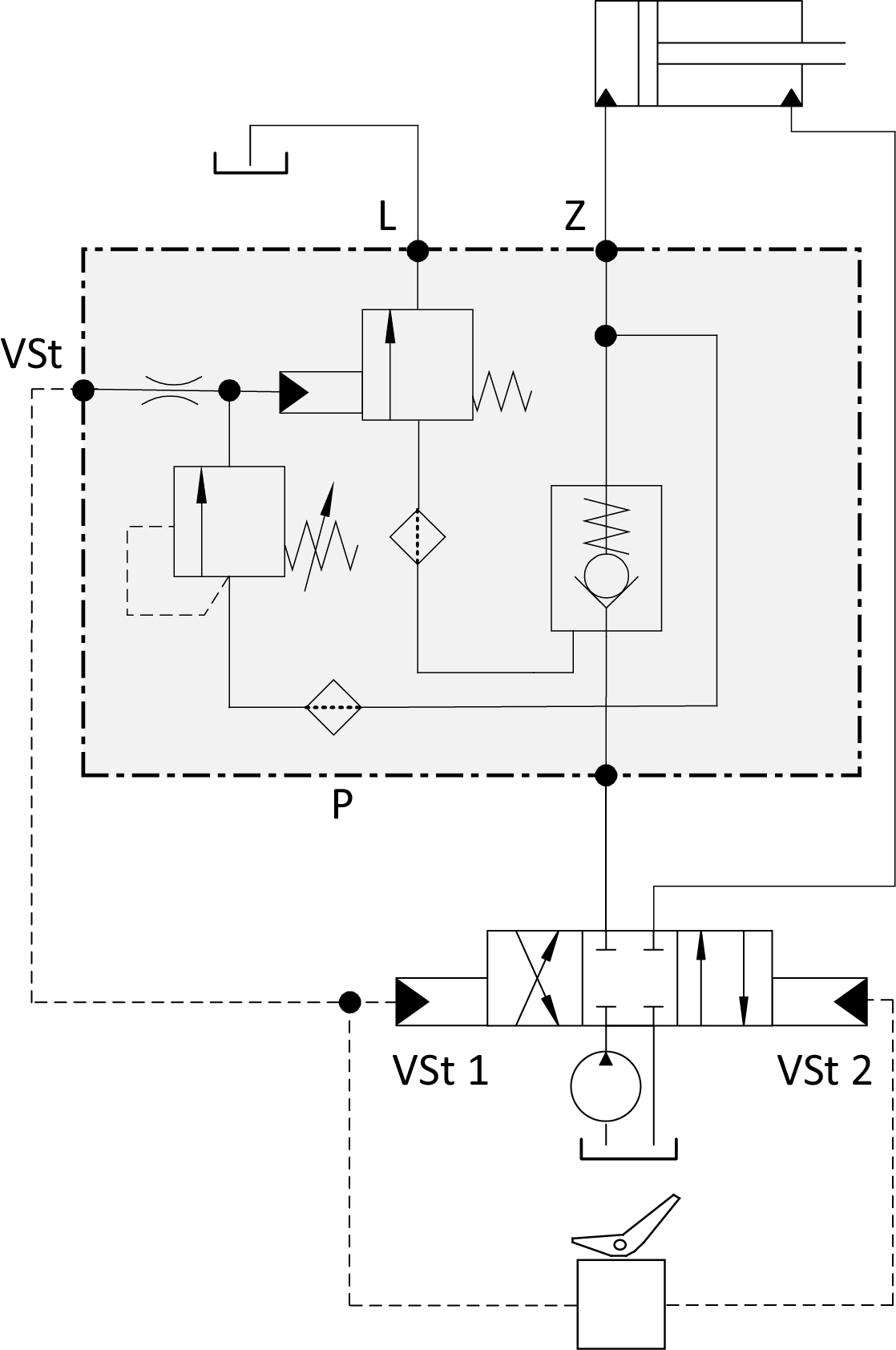

Leakage in the neutral position can occur on directional valves in spool design, which can lead to a slow drop of the boom or the load. If this is not wanted, it can be prevented by a leak-free locking valve. The volume flow flows freely from port P to port Z via a check valve. If no pilot pressure is present, the consumer is locked at port Z without leakage. To open Z to P, a pilot pressure must be applied to VST (> 6bar). Usually hydraulically operated control valves open at a pilot pressure between 7 and 10 bar. Due to the fact that the pilot-operated check valve is opened prior to the main control valve´s spool, a release shock can be avoided. If actuated, a minimum volume flow flows into the leak oil connection. To protect the consumer against external influences, a pressure limiting function is integrated. The pressure relief valve must be set approximately 10 bar lower than the pressure control in the main control valve

Anwendungen

- Excavators

- Wheel loaders

- Material handling machines